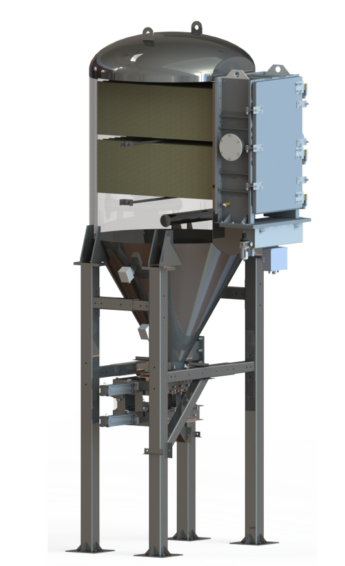

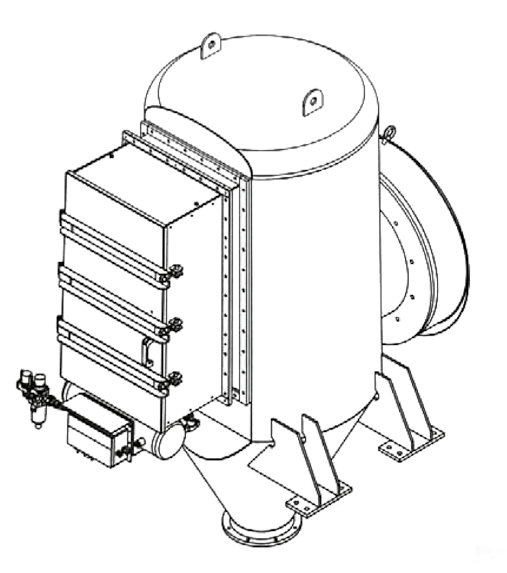

Filter-separator is being installed on the support frame in the place, determined by the project documentation. Filter-separator is a pocket filter with flat filtration elements. Regeneration of filtration elements is done on-line during working process, consequently in automatic mode (and also after switching the system off) by pulse purging by compressed air at 4-7 bar pressure. Activation of regeneration process is done on the basis of the pressure drop value between dirty and clean chambers of the filter. Number and length of pulses are being set up on the control panel. Cleaning efficiency of the dust capturing unit is 99.95%. Unloading of material, collected and captured in filtration module, is done continuously with lock chamber feeder or double cutting damper. Lock chamber feeder and double cutting damper provide portional unloading of collected dust, without additional suction of air or stoping of the system.

| Capacity | up to 1200 cmh | up to 2000 cmh | up to 3000 cmh |

| Filter reinforcement | |||

| Control box | |||

| Box with integrated magnetic valves | |||

| Residual dust concentration | |||

| Standard operating temperature | |||

| Optional operating temperature | |||

| Temperature of inlet airflow | |||

| Filtration elements | |||

| Material of filtration elements | |||

| Filtration surface area | |||

| Voltage | |||

| Double cut damper/lock chamber feeder ZS200 | |||

| Oil and moisture separator | |||

| Consumption of compressed air | |||

| Pockets removing | |||

| Maximum operating weight | |||