DCSC-M-6 units (without built-in compressor) and DCSC-M-6-K (with built-in compressor) are designed for local removal and purification of air from aerosols and dust particles generated during welding, cleaning, grinding of metals, as well as similar types of processing of various materials.

Working principle

The principle of operation of the filters is based on the local capture of polluted air, the mechanical cleaning of air from harmful substances and the return of purified air to the production room. Air recirculation reduces energy costs for the general ventilation of rooms, heating, maintenance of the filter itself and protects the workers of the enterprises from the effects of harmful substances released during technological operations.

Working conditions

DCSC-M-6 filters are designed for continuous operation in enclosed spaces under the following conditions:

● mode S1 according to GOST IEC 60034-1-2014;

● ambient temperature from plus 5 to plus 45 °С;

● relative humidity no more than 80% at plus 25 °С;

● the temperature of the transported airstream should not exceed plus 80 °С;

● the air stream must be non-explosive, must not contain aggressive vapors and gases, sticky and fibrous dust, as well as particles and materials prone to smoldering and spontaneous combustion.

● High performance up to 2400 m³ / h with low energy consumption – 1.5 kW;

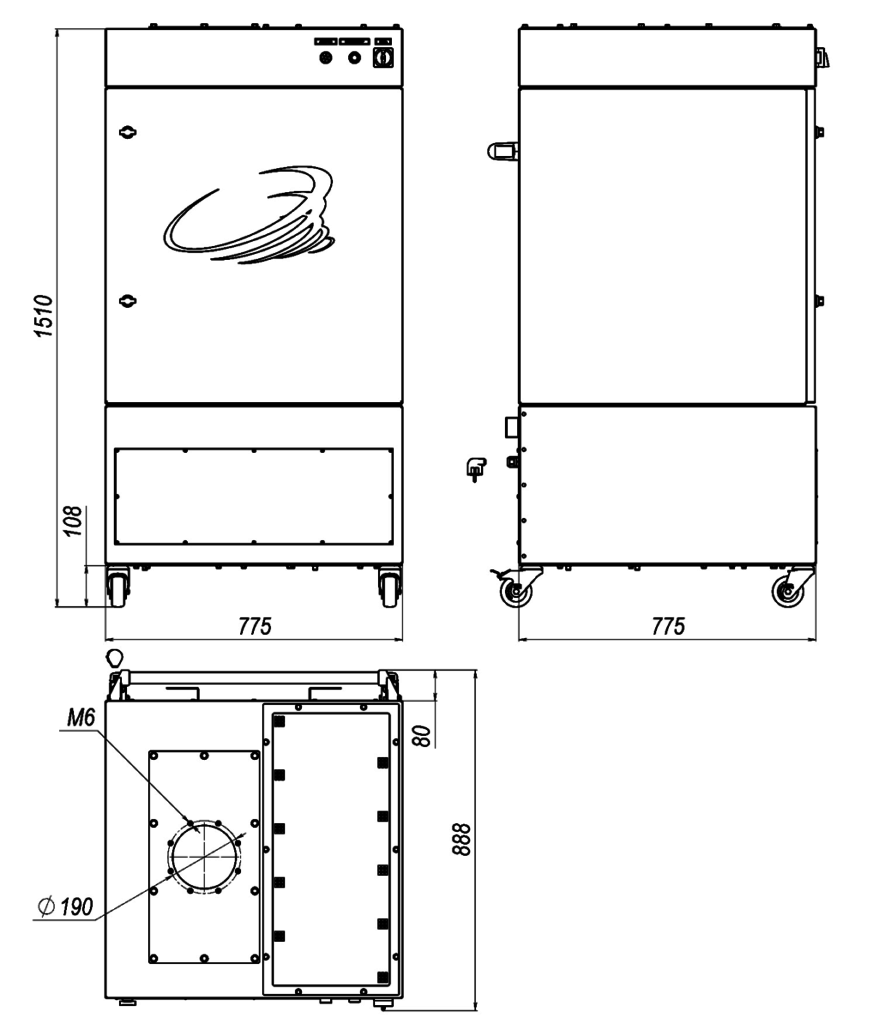

● Compact body – 775x888x1520 mm;

● Low noise level – 75 dBA;

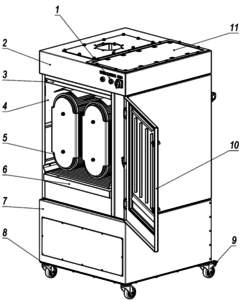

● Horizontal flat-oval cartridges (2 pcs.) With high filtration class;

● Intelligent automatic cleaning system with ΔP function (extends cartridge life, reduces power consumption and compressed air consumption);

● Light and sound alarm of maximum contamination of the cartridge;

● Simple system of pressing and fixing cartridges for easy filter maintenance;

● Possibility of installing two exhaust devices ø160 mm or one ø200 mm or ø160 mm;

● Built-in oil-free compressor (option);

● Activated carbon filter (optional);

● Two-stage spark protection that reduces the risk of fire;

● Outlet of purified air up;

● Filter operation controls are located in the upper part of the housing for the convenience of operating personnel;

● The filter control keys are duplicated on the funnel of the exhaust device;

● Reinforced swivel wheels with locking mechanism to ensure filter maneuverability and ease of operation in confined spaces;

● Convenient pull-out dust collector.

| Description | ||

|---|---|---|

| Maximum air consumption, m³ / h | ||

| Power consumption of the filter, kW | ||

| Filter supply voltage, V / Hz / Phase | ||

| Motor power, kW | ||

| Max. compressed air consumption, l/ min. free air: - factory setting (1 pulse / min.) - manual setting (up to 3 pulse / min.) | 135 | |

| Pressure of the supplied compressed air (working), MPa (bar) | (5.0 – 5.5) | |

| Filteration class (DIN EN 779-93) Filteration class (DIN EN 60335-2-69 ) | M | |

| Active filtering surface, m² | ||

| Cartridge Type / Material | ||

| Max. differential pressure ∆P, Pa | ||

| Extra cleaning stage | ||

| Noise level, dBA | ||

| Diameter of the inlet for the pipe, mm | ||

| Overall dimensions, mm | ||

| Filter weight, kg* | ||

| Degree of protection in accordance with GOST 14254-80 | ||

| Mode of operation | ||

| Compressor type | ||

| * excluding the mass of the exhaust device | ||

|

|