Mobile mechanical self-cleaning filters of DCSC-M-5 series are intended for local capturing and cleaning of air from aerosols and dust particles, formed during welding, grinding, polishing of different materials and similar applications. Filters are designed for permanent and temporary workplaces in workshops of various industrial facilities, laboratories, training and certification facilities, and others.

Working principle of DCSC-M-5 series filters is based on local capturing of polluted air, mechanical cleaning of air from hazardous components by passing the air through filtration cartridge and returning the clean air back to industrial premises. Recirculation of air allows decreasing of electricity consumption for general ventilation and air conditioning. FIlters protect factory workers from influence of hazardous substances, allocated during technological operations.

Specifications and advantages

- Integrated compressor

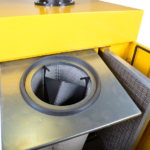

- Vertical fast-detachable cartridge

- Low noise level – 66 dB

- Two-stage spark arrestor

- Top side air outlet

- Electronic differential pressure gauge

- Automatic cleaning on the basis of deltaP function

- Led and sound indications

- Automatic cleaning after fan stop

- Remote control on the extraction arm nozzle

- Compact body shape

- Application of DCSC-M-5 is a standard solution for workplaces with space and noise level limitations. Well suitable in case of absence of compressed air connection.

- DCSC-M-5 has low noise level, compact dimensions and integrated compressor, which allows using it for urgent equipment of temporary and stationary workplaces in industrial workshops, laboratories, training, and other facilities.

- DCSC-M-5 has two-stage spark arrestor, consisting of special multi-layer wired mesh of stainless steel and large steel reflector shield, which allows using this filter for applications with large number of sparks.

- As an option, the extraction arm can be equipped with buttons on extraction nozzle for switching on/off the led lighting and fan right from the workplace.

- New controller with differential pressure gauge takes care of fully automatic cleaning process on the basis of cartridge saturation level (deltaP function). This allows using DCSC-M-5 in educational and training facilities, making is very simple to control, demanding no special set-up or maintenance.

DCSC-M5 are suitable for continuous operation in closed premises at the following conditions

- Surrounding temperature 5 to 45 °С

- Relative humidity not more than 80% at 25 °С

- Temperature of airflow entering the unit – below 60 °С

- Airflow must be not explosive, containing no aggressive vapours and gases, no sticky of fiber dust and no combustible particles

| Parameter | Value |

|---|---|

| Maximum airflow, cmh | 1200 |

| Max consumption of compressed air, liters of free air per minute - factory default (1 pulse per minute) - manual setting (up to 3 pulses per minute) | 45 135 |

| Integrated fan power, kW | 1.1 |

| Fan power source voltage, V/Hz/Phases | 220/50/1 |

| Control box power source, V/Hz/Phases | 24 |

| Control box power, kW | 0.1 |

| Compressed air pressure (working), atm | 5,0 - 5,5 |

| Cartridge positioning | Vertical |

| Active filtration surface area, sq.m | 12 |

| Type of filtration material | Polyester with PTFE membrane |

| Filtration class EN 779-2014 (DIN EN 779-93) | F9 |

| Filtration class DIN EN 60335-2-69 | M |

| Noise level, dB, below | 66 |

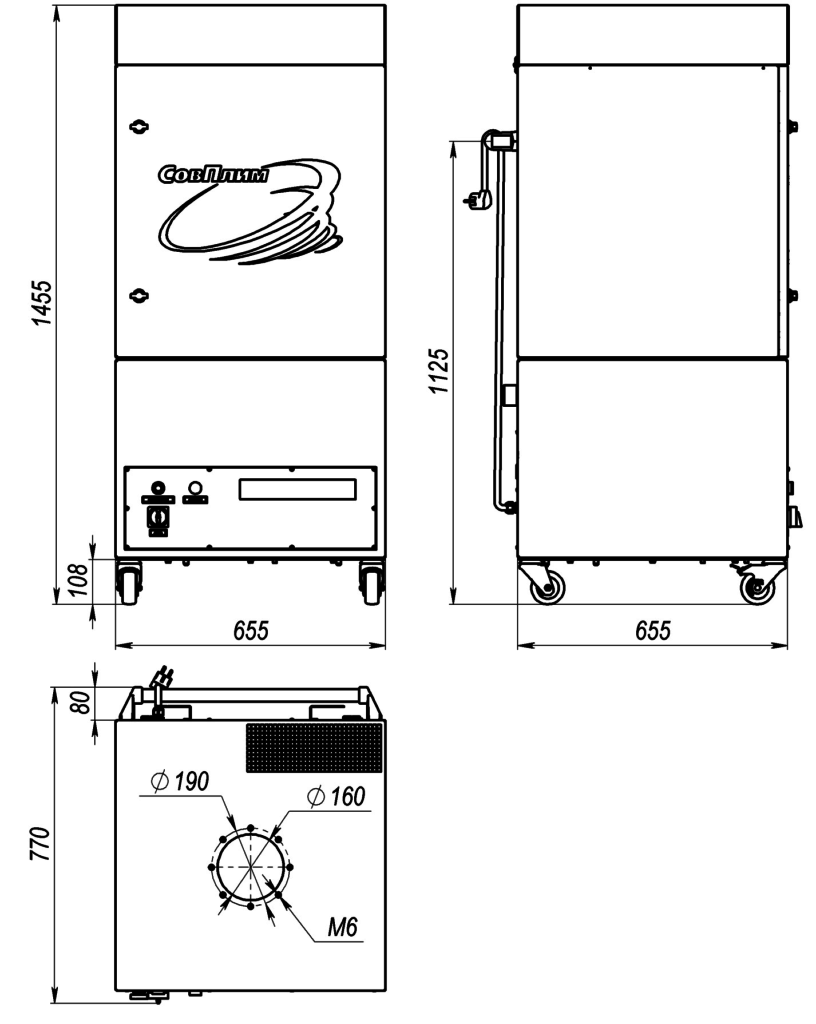

| Dimensions (WxL(w/out handle)xH), mm | 655x655x1455 |

| Inlet diameter, mm | 160 |

| Number of inlets | 1 |

| Weight w/out compressor, not more than, kg | 150 |

| Protection class | IP54 |

| Working regime | continuous |

| Parameters of compressed air for DCSC-M-5C | Value |

|---|---|

| Compressor power, kW | 0.5 |

| Working pressure, bar | 8 to 10 |

| Noise level, dB, below | 52 |

| Power source voltage, V/Hz | 220/50 |

| Protection class | IP54 |

| Type of compressor | No oil |